About Us

Hilton was well known in the rollforming industry and had earned a reputation as an original and innovative designer and many customers followed him to Premier to manufacture for them. The business expanded rapidly with more varied and challenging profiles and with the purchase of several more machines, the company relocated to a larger facility in Smithfield.

Hilton was well known in the rollforming industry and had earned a reputation as an original and innovative designer and many customers followed him to Premier to manufacture for them. The business expanded rapidly with more varied and challenging profiles and with the purchase of several more machines, the company relocated to a larger facility in Smithfield.

During 1995, Singapore-based company, Techsteel Corporation became involved and the company name changed to Premier Steel Technologies.

In 1998 the company moved to a larger premises again to its current location at 229 Newton Road, Wetherill Park, a 2,500 square metre factory and currently employs approximately 16 people, concentrating on custom rollforming manufacturing.

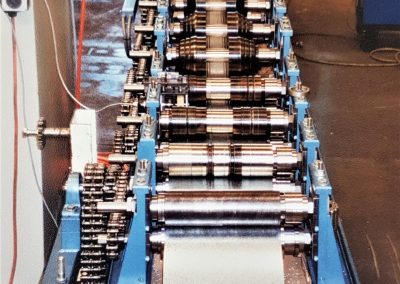

Custom Machinery

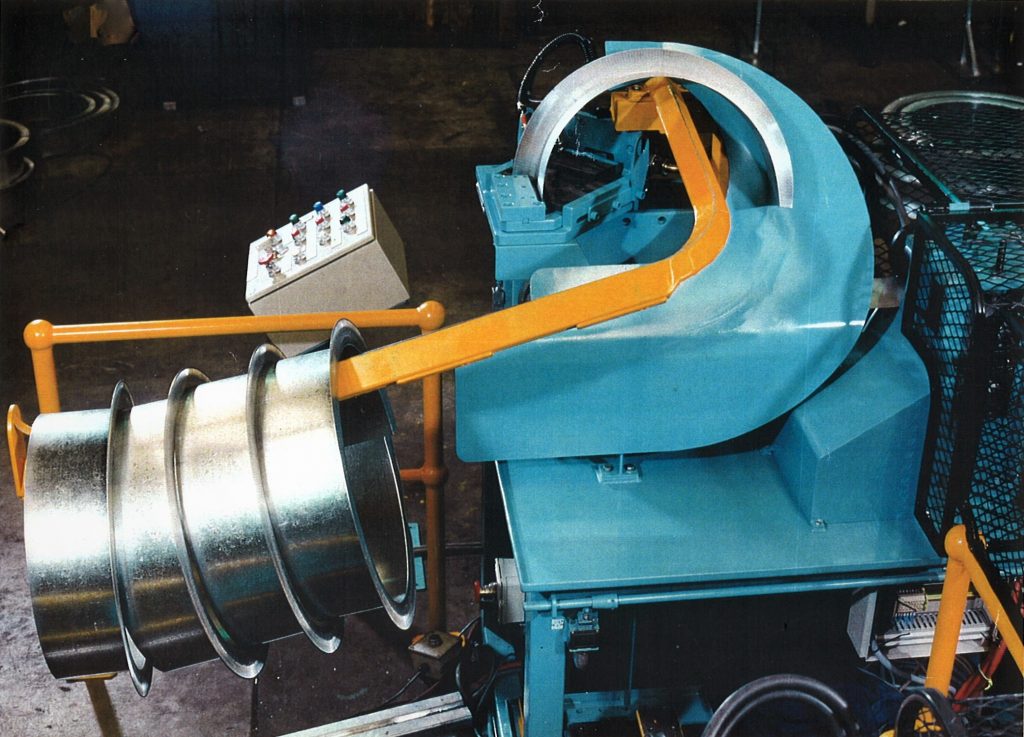

From 1992, Premier Steel developed a relationship manufacturing several products for BHP and were commissioned by their Export Division in Port Kembla to design and build two state-of-the-art production lines to make the internal and external protective rings for their coil packaging facility.

From 1992, Premier Steel developed a relationship manufacturing several products for BHP and were commissioned by their Export Division in Port Kembla to design and build two state-of-the-art production lines to make the internal and external protective rings for their coil packaging facility.

After several months designing and building, both machines were successfully trialled and delivered to their Wollongong premises and are still in operation today. The story was featured in the BHP Hotline magazine and also in Metalworking Australia with both machines being pictured on the cover.

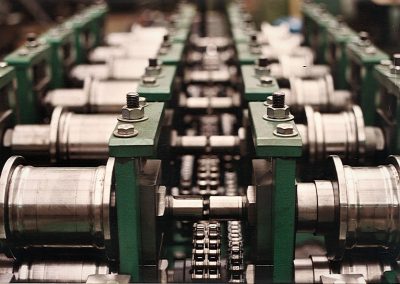

Premier was also commissioned to build the entire production facility for a Steel House Frame company called Uniframes, who were one the first companies in the building industry to utilise light gauge hi-tensile steel profiles in the growing steel house frame market.

The customer had been told that some of the profiles could not be done, so was thrilled when Premier took on the project. The system included many innovative technologies, with the design and building of eight production lines, consisting of a top and bottom plate wall profile, stud machine, top and bottom chord truss profiles and an in-line high frequency welding machine to make the truss webbing. Each machine was fully integrated with CAD design and interface software and could be programed to manufacture the exact lengths for each frame design, which were assembled on specialised truss and wall assembly tables, designed by Premier. The system won an Australian Design Award and was the first light gauge steel house frame design to achieve a cyclonic rating.

The customer had been told that some of the profiles could not be done, so was thrilled when Premier took on the project. The system included many innovative technologies, with the design and building of eight production lines, consisting of a top and bottom plate wall profile, stud machine, top and bottom chord truss profiles and an in-line high frequency welding machine to make the truss webbing. Each machine was fully integrated with CAD design and interface software and could be programed to manufacture the exact lengths for each frame design, which were assembled on specialised truss and wall assembly tables, designed by Premier. The system won an Australian Design Award and was the first light gauge steel house frame design to achieve a cyclonic rating.

Today, Premier Steel Technologies focuses more on product manufacturing and offers an in-house rollset and tooling design service, but does not build machinery for external companies.